09 January, 2026

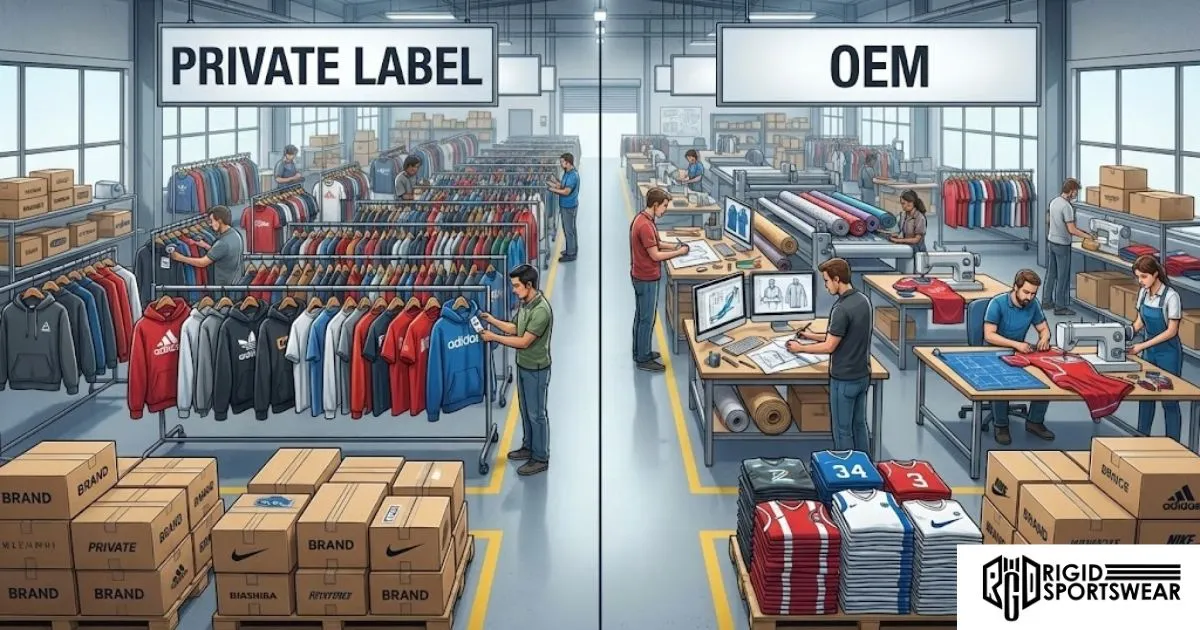

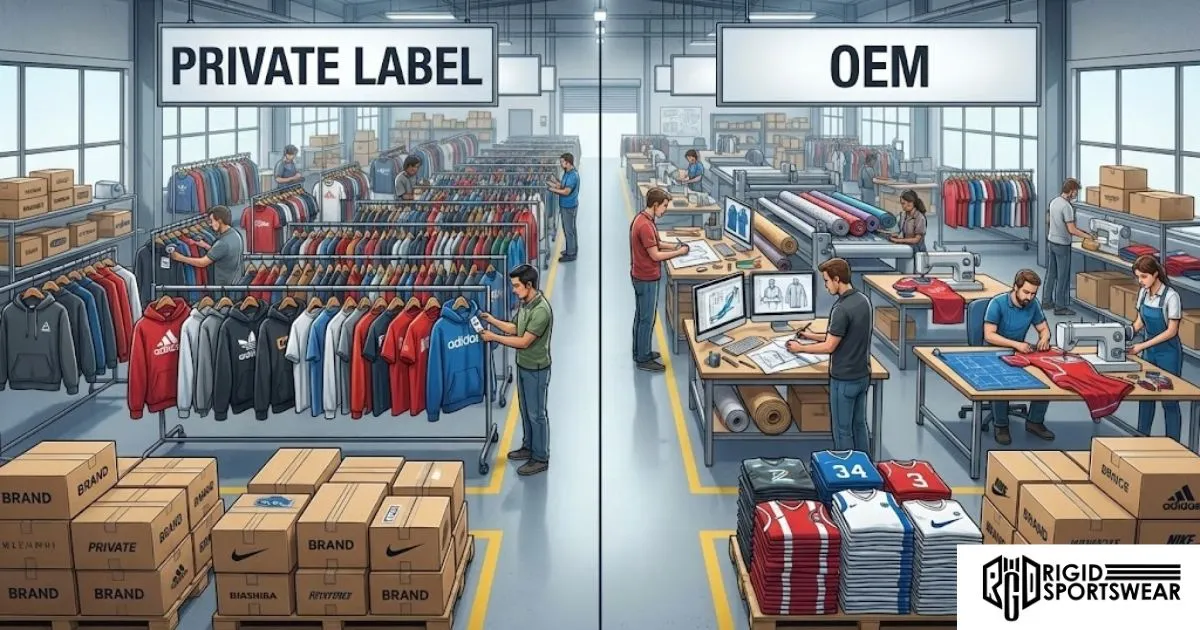

Private Label vs OEM Sportswear Manufacturing: Which Is Best for Your Brand?

28 December, 2025 | jhon smith

You are a proud brand owner of your carefully curated clothing line. But the apparel manufacturing industry can be competitive in today’s neo-capitalism. Only the smartest get to survive. Whether you are a private label or an OEM defines the nature of your label. This sets the parameters of production. Important factors like quality, scheduling, design, and distribution depend on this. Understanding these lets you make a wise choice. This dictates your efficiency and consistency in quality. This is your guide to choosing the top custom jersey maker in India.

What is a Private Label?

Purchasing pre-designed goods from producers of generic sportswear is known as private label manufacturing. You choose from their current selection. Be it tights, sports bras, pants, or jackets. Here, you add your own branding components to their products. For example, labels, logos, and personalized packaging. You concentrate on marketing and sales. While the manufacturer manages production. It is work divided.

What is an OEM?

The Original Equipment Manufacturer allows brands to collaborate with a factory. OEM manufacturing provides a cooperative relationship in which the manufacturer creates sportswear in accordance with your requirements. The manufacturer manages production logistics, procurement, and assembly. You supply the designs, technical sketches, fabric specifications, and quality standards.

Private Label or OEM?

If you are confused between the two, that is a justified confusion. But it is easy to choose once you understand the advantages and limitations of each kind of manufacturer. It is how you choose the best custom jersey maker in India.

Understanding a Private Label

The main benefits of private labelling are ease of use and rapidity. Because most manufacturers keep ready-to-customize inventory. This is why you can launch products in a matter of weeks as opposed to months. With far lower minimum order quantities—typically between 50 and 100 pieces per style—this strategy allows startups and small companies to evaluate market demand. All without having to make large capital investments. Another significant advantage of private labels is cost predictability. You avoid development fees, sample costs, and technical design charges. This is because designs and patterns already exist. They may be your best corporate wear manufacturer.

Restrictions of Private Labels

- There is minimal distinction between rivals who might purchase from the same producer.

- You have very little influence over fit requirements, construction specifics, or fabric choice.

- The above makes creating a distinctive brand identity challenging.

Understanding OEM

OEM manufacturing provides a cooperative relationship. In this, the manufacturer creates sportswear in accordance with your requirements. The manufacturer manages production logistics, procurement, and assembly. Your job is to supply the designs, technical sketches, fabric specifications, and quality standards. This gives you independence as a creator. It may be how you find your top custom jersey maker in India.

The advantages of OEM are manifold. You get total creative control over designs, producing genuinely original goods. This further gives you the sole possession of your requirements and designs. It enhances your capacity to create novel textiles, fits, and features. It gives you Increased brand distinction in a crowded market.

Limitations

- Greater minimum order quantities, often between 500 and 1,000 pieces for each style

- Longer development times, usually between three and six months from conception to completion

- Large initial expenditure on tooling, pattern-making, and sampling.

The Hybrid Method

If you want to have the top custom jersey maker in India, the hybrid method is your best bet. As they grow, many prosperous sportswear companies’ progress. Then they switch to OEM manufacturing after beginning with private labels to confirm demand and make money. With this hybrid approach, you may test the market with little risk while accumulating funds and consumer insights that guide future bespoke development.

Conclusion

Some firms continue to use both strategies concurrently. They like spending OEM resources on signature items that build their brand identity while using private labels for necessities. Cash flow is maximized by this well-rounded approach. If you want the best activewear apparel made in India, contact Rigid Sportswear.

Recent Posts

MOQ (Minimum Order Quantity) Explained: How I

Cotton V/S Polyester Fabric: Which is best fo

Private Label vs OEM Sportswear Manufacturing

How to Choose the Right Sportswear Manufactur

Trending Jersey Designs for Inter-College Com

How to Choose the Best Sportswear for Employe

Categories

Download now

Download now