06 January, 2026

MOQ (Minimum Order Quantity) Explained: How It Works in Sportswear Manufacturing

09 January, 2026 | jhon smith

In sportswear manufacturing, the Minimum Order Quantity (MOQ) is a key factor that shapes how production orders are planned and accepted. MOQ is essential for sportswear manufacturers to manage the production lines, acquire the required fabrics, and perform the stitching and printing processes. Sportswear is more complex than regular clothing since it requires technical fabrics, various sizes, and customization options like logos and sublimation. To keep operations smooth and costs down, t-shirt printing manufacturers use quantity thresholds.

Minimum Order Quantity (MOQ) is very important for brands and purchasing teams as it impacts design, pricing, and, most of all, growth. MOQ will directly impact what kinds of fabrics, what colors, and what sizes will be offered, and even the rate of production. With MOQ in their understanding, sportswear brands will be able to make informed, optimized, and effective decisions while building long-term relationships with their manufacturers, while still ensuring quality.

Different Applications of MOQ in the Sport Equipment Manufacturing Industry

MOQ impacts order acceptance, costing, manufacturing, fabric selection, customization, and scheduling for sportswear manufacturing. Minimum quantities of specialized fabrics for lower costs must be taken into account by brands in the MOQ.

Applied for design

The minimum order quantities are fixed by the manufacturer for different styles of products. You require a minimum order quantity for different designs of jerseys. You are not allowed to add the order quantity of different styles. It is important to achieve the required order minimum of both designs to finalize the order. The best corporate clothing suppliers must adhere to the above point if you are in need of the best suppliers.

Split across sizes

In factories, there will be flexibility in terms of size varieties, as long as the cumulative order quantity for the sizes is met. This implies that you can order varying sizes, which include Small (S), Medium (M), Large (L), and Extra Large (XL). There might be a certain quantity needed for each of the sizes offered.

Affects customization options

The degree to which one can customize also impacts the number of items that businesses will need to order. If companies want to work with stock colors and prints, they can easily order lower quantities, which will give them all the flexibility they need. But when it comes to other areas, such as sublimation, embroidery, and maybe customized colors, it will require businesses to place larger orders. If businesses are interested in creating customized fabrics, it will also call for higher minimum orders.

Affects production schedule

The advantage of large quantity orders is their priority processing, ensuring the commencement of production is quicker, thus a quicker delivery time. Small orders might have a delay in processing, thus may be done during the off-season, causing a waiting period.

Guides scaling strategy

Brands may begin by choosing the designs based on requirements in the market. As the brand gains popularity, it may start to broaden its designs based on the demands of its customers. It may introduce new designs based on the preferences of its customers. In this way, the brand shows its adaptability while also satisfying the customers’ preferences.

Applied per color

Usually, every available color will have a minimum order. For instance, if a customer wishes to place an order for jerseys in bright red and dark blue, they will be required to meet the minimum order in both colors. This is to ensure that the different colors of the jerseys will be in adequate supply so that every jersey will stand out in its own special color.

Conclusion

The concept of Minimum Order Quantity (MOQ) is critical when it comes to sportswear manufacturing. The idea of MOQ determines manufacturing process efficiency, cost, and quality control. The concept allows companies to determine design, fabrics, and prices. It is critical information that is valuable to every sportswear clothing brand in all aspects. The concept educates sportswear brands on how to reduce costs and manage their orders.

Recent Posts

MOQ (Minimum Order Quantity) Explained: How I

Cotton V/S Polyester Fabric: Which is best fo

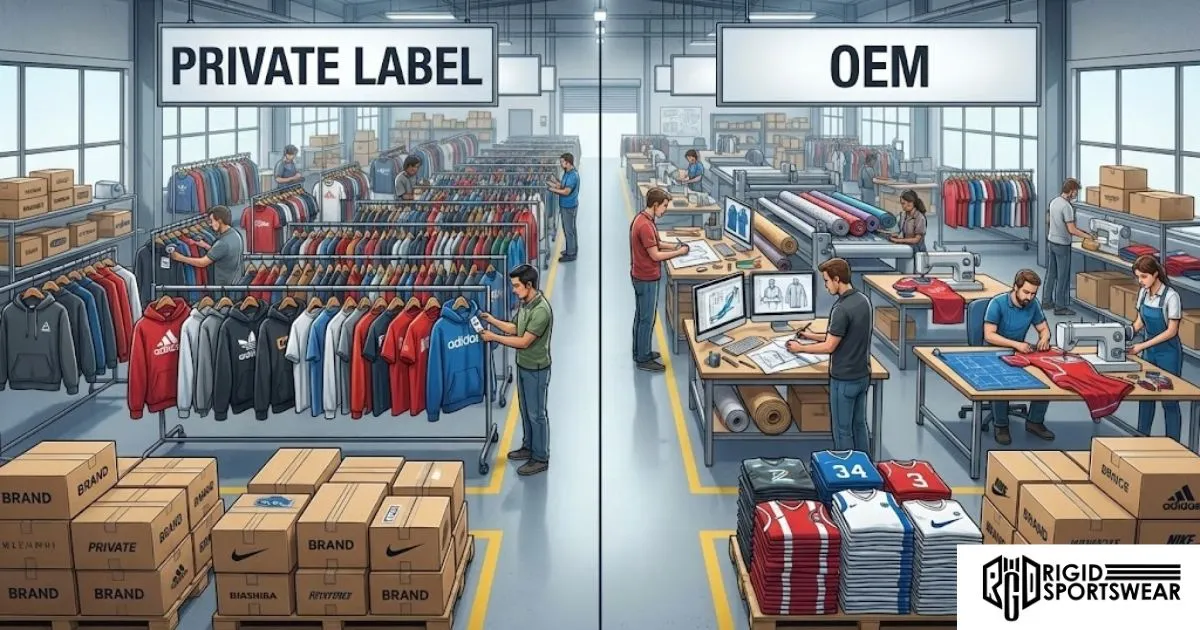

Private Label vs OEM Sportswear Manufacturing

How to Choose the Right Sportswear Manufactur

Trending Jersey Designs for Inter-College Com

How to Choose the Best Sportswear for Employe

Categories

Download now

Download now